- Contact Person : Mr. zhang weiping

- Company Name : GLOBAL JOINING TECHNOLOGY CO., LTD.

- Tel : 86-579-82276776

- Fax : 86-579-82277211

- Address : Zhejiang,Jinhua,NO.988.West Road Binhong.Jinhua.Zhejiang.China

- Country/Region : China

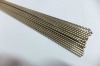

Related Product Searches:Fluxcoated copper-zind brazing alloys welding round rod,High Quality,welding rod, copper zinc welding rod,HS221

Copper-Zinc Brazing Alloys are suitable for gas-flame brazing, high temperature brazing, salt bath dip brazing of copper and copper alloys , nickel, cast iron and hard alloys. While brazing by oxyacetylence, to heat with oxidized flame quickly can lessen evaporation of Zinc and prevent gas porosity due to over-oxidization.The optimun joint gap should be 0.025-0.1mm. Flux is also necessary for good seam.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fluxcoated copper-zind brazing alloys welding round rod